environmental benefit of wastewater treatment plants in mountainous areas in the alps

|

Comparison of technology, costs and environmental benefit of wastewater treatment plants in mountainous areas in the alps |

|

B. Wett, W. Becker, K. Ingerle

Abstract

Key-words

Introduction

Effects of overloading (Biocos pilot plant Zirl)

Effects of underloading (SBR-plant Meissner

Haus)

Conclusion

Acknowledgement

References

The smaller the wastewater treatment plant,

the higher the variation of the influent load. This wellknown fact causes

major uncertainties to a stable operation of small activated sludge systems.

Especially the wastewater load of tourist resorts varies in the range between

almost zero and total overloading within days. What are the dynamic effects

of transient loads on the elimination rates and the sludge characteristics

of a low loaded system and how long does it take for this system to recover

from peak loads (e.g. weekend rush at tourist facilities). Such questions

are studied in this presentation, considering data from a full-scaled pilot

plant and from operation examples of small activated sludge plants in mountainous

areas.

Activated sludge, small wastewater treatment

plant, sludge load, load variation, settling

The activated sludge process has been experienced an intense development during recent years and the available technical equipment has been improved. In the same time the emission standards have been enhanced and nutrient removal has become the crucial demand on advanced elimination processes. Nevertheless concerning small wastewater treatment plant applications engineers have to change their approach: The process layout does not aim at sophisticated strategies running under optimum operation conditions. The basic goal to meet is a robust technology which handles extreme boundary conditions and varying disturbances. Hence a stable organic carbon elimination – an obviousness in well maintained larger treatment plants – is still a matter of concern in this application. Especially load variations of a few hundred percent give a challenge to any treatment strategy. An interesting aspect of this topic is the dynamic behaviour of an activated sludge system under the influence of extreme load conditions – overloading and underloading.

The hydraulic capacity of an activated sludge system shows well defined limits and the effect of hydraulic overloading is obvious and instantaneous: A wash out of solids. This presentation considers organic and not hydraulic overloading. Especially at remote tourist facilities with low sanitary standards for example in mountainous areas wastewater with very high concentrations of both soluble and solid components is produced. Therefore in these applications the organic loading represents the major design criterion.

As commonly known a sludge loading higher than 0,5 kg BOD / kg SS should be avoided otherwise the settleability of sludge suffers and the SVI increases reasonably. Therefore the usual plant design aims at a sludge loading of about 0,2 kg BOD / kg SS in order to ensure a stable carbon elimination. Despite a correct design of the small wastewater treatment plant in many cases single events with loadings up to 1,0 kg BOD / kg SS and more cannot be avoided. If this happens a well trained operator would have the possibility to release partially the plant via a by-pass. In this case a short term load to the receiving water is taken into account in order to prevent a long term harm to the biological system of the treatment facility. A small automated plant running on its own would probably experience negative effects:

To demonstrate the dynamic behaviour of an overloaded activated sludge system a Biocos-pilot plant is considered. The Biocos-strategy combines principles of the conventional continuous flow activated sludge process and the single tank technology and consists basically out of two hydraulically connected reactors: One aerated reactor and one cyclic operated sedimentation- and circulation tank which replaces the secondary clarifier and the sludge recycle unit (Ingerle, 1998). Therefore the general results of the performed experiments are applicable to any type of continuously or intermittently operated activated sludge system.

|

|

(organic influent load and aerobic sludge loading) |

The biochemical reactors comprise a volume of about 2,5 m3 and have been fed stepwise in order to simulate a typical daily load variation. The observation period lasted for almost half a year. After a low loaded period of about three months when advanced nitrogen elimination and steady state conditions have been achieved the loading was significantly increased. Both the influent concentration and the suspended solid concentration in the system have been changed whereas the hydraulic conditions have been kept constant (Hagner, 1998).

The initial influent concentrations of typical municipal wastewater have been pushed to concentrations often measured at tourist facilities in the Alps (130 mg NH4-N/l, 1200 mg COD/l) by adding beer and NH4CL. Fig.1 shows the slow descent of the sludge loading (0,08 kg BOD / kg SS) due to increasing sludge concentration during the low loaded period. Then the influent concentrations have been increased within one step which resulted in a sludge loading of almost 0,5 kg BOD / kg SS. After two more weeks the SS concentration was dropped and the remained sludge was loaded by almost 1,1 kg BOD / kg SS.

The COD-influent concentration during the high loaded period was about four times higher than during the low loaded period (increase from about 300 mg COD/l to 1200 mg/l). In the same time the effluent values increased from 20 – 60 mg COD/l to 50 – 150 mg COD/l. That means a constant COD elimination rate of about 90 % hardly influenced by the actual sludge loading (this elimination rate considers only the biological treatment and not the primary settlement). The organic degradation process including adsorption processes shows amazing capacities regarding that the air supply system was on its limits and the oxygen concentration near zero. In contrast to the COD elimination process the nitrification rate decreases significantly with decreasing sludge age and oxygen concentration.

|

|

Fig. 2: COD- and NH4-elimination rates under varying load conditions |

Fig.3 represents a vivid description of the influence of the organic sludge loading on the sludge settleability, of the time delay of these effects and of the required time period to recover from these effects: An average sludge loading of 0,2 to 0,3 kg BOD / kg SS results in a stable sludge volume index around 80 ml/l/g. When the load decreases to half of the original value, the SVI is reduced to a similar extend. Immediately after the influent concentration has been increased and the load reached 0,4 kg BOD / kg SS, the SVI returned to its original value of 80 ml/l/g. It was not until the peak load of 1.1 kg BOD / kg SS, that the SVI became unstable. After the short load event the SVI still keeps continuously growing, while the average sludge load was adjusted again at 0,4 kg BOD / kg SS. The peaks of the two curves differ distinctly by seven days representing the delay between effect and cause. The highest sludge volume index was reached at a value of 280 ml/l/g and then the sludge settleability recovered within two more weeks.

|

|

Fig. 3: Dynamic behaviour of the sludge settleability due to a peak load |

These measurements confirm that a sludge

loading of 0,5 kg BOD / kg SS is a key value for a reliable settling process.

Due to the time delay between a peak load and its effect on the SVI the

complete degradation of this peak load is not questioned. But after such

a single load event the waste sludge withdrawal has to be intensified in

order to keep a constant sludge volume and to prevent a wash out of solids.

Therefore the system suffers an obvious loss of a great part of its elimination

capacity. Cyclic activated sludge systems seem to represent the most reliable

strategy to handle an unstable SVI. Since the excess sludge discharge facility

is installed at a defined level, the sludge blanket height is fixed at this

level despite varying sludge characteristics.

If overloading conditions are prevented by a generous plant design, other problems can occur. To demonstrate the lower limit of a possible load variation an operation example of a SBR-works of an Alpine tourist hut is described. The SBR-reactor of this treatment plant has a volume of 14 m3 and was originally designed for a maximum load of 120 p.e. Additionally the considered system has a very high puffer capacity: The influent flow is fed to the first chamber (15 m3 volume) and then to the second chamber (29 m3 volume) of the primary settler which also serves as a waste sludge storage tank. During the last season the actual load was much less than assumed: The week before the three days measurement period started the average load was 10 p.e. and at the beginning of the measurement the load reached 60 p.e. The wastewater of the 1700 m above sea level situated Meissner Haus reached an average temperature of 13,2 °C.

|

|

Fig. 4: Off-line measurement data of the SBR-works at the "Meissner Haus" |

At a first look at the site the yellow-brown colour of the effluent water and the low sludge concentration in the SBR-reactor (0,27 g SS/l) indicated a poor effluent quality and a failure of the plant`s performance. The chemical analysis of the samples revealed, that complete nitrification was achieved. This contradiction is caused by excessive sludge stabilisation: The organic part of the biomass had been reduced by continued biological degradation while still enough nitrifying organisms had been kept within the system corresponding to the ammonia supply. As a final product of the biological degradation processes humic substances had been produced. These substances consist out of phenolic and carboxylic functional groups and reach high molecular weights up to 100.000 g/mol and more. Due to the colloidal character of the humic substances and their typical colour the effluent water showed a bad quality and an average COD concentration of 99 mg/l was measured. This organic concentration is hardly degradable which is verified by low BOD-effluent concentrations (8 mg/l in average) and a high COD/BOD ratio of about 12.

Fig.4 shows the performance of the SBR-plant at the Meissner-Haus: Due to the inhomogeneous characteristics of the influent wastewater the daily average influent concentrations are not directly measured but calculated from the counted person equivalents and the measured water consumption. The concentrations in the second chamber of the primary settler (waste sludge storage tank) are much lower than the influent concentrations because of the waste sludge withdrawal. At the end of each operation cycle of the SBR-reactor when the sludge has settled the waste sludge is discharged at a level of about 70 cm beneath the water surface. The discharge pump operates two minutes and recycles a mixture of waste sludge and already treated supernatant water back to the settler causing a dilution of the influent concentration. Only the NH4-N concentration in the settler is quiet high because of resolution processes. In general the recycle of treated water to the settler improves the puffer capacity of the system reasonably. Therefore the influent peak load has hardly any effect on the effluent concentration.

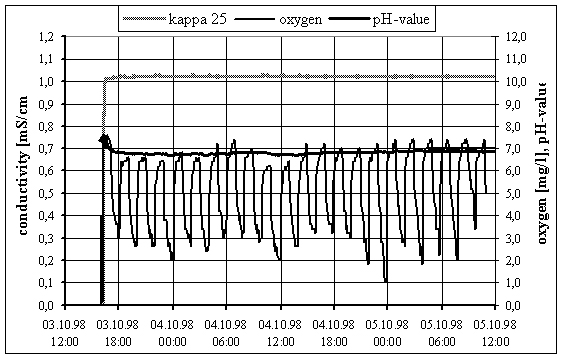

The measured nitrate effluent concentration indicates an incomplete denitrification performance. The on-line oxygen measurement (see Fig.5) confirms that the low biomass concentration leads to a low oxygen demand. Starting from a high oxygen level at the end of the aeration phases the available oxygen is consumed very slowly. Therefore never a anoxic milieu is reached and denitrification is not promoted.

|

|

Fig. 5: On-line measurement data of the SBR-works at the "Meissner Haus" |

Two correctional measures have been taken

in order to prevent an excessive stabilisation of the biomass in the SBR-reactor:

The control system of the SBR-strategy was provided with a three-stage

programme. Depending on the actual load conditions the programme can be

switched between these three programmes and the adjusted time interval

of the aeration phase alteres. Moreover the waste sludge recycle was fed

to the first chamber of the primary settler. This measure causes a constant

load of dissolved organic matter from the primary sludge.

The actual sludgeload of a small activated

sludge systems hardly influences its elimination rate concerning organic

matter. The main problems due to load variations effect the sludge characteristics.

The sludge settleability and as a consequence the available active and

aerated biomass determines the elimination capacity: On one hand overloading

increases the SVI and therefore the suspended solids concentration needs

to be lowered in order to prevent a wash out of solids. Since a careful

maintenance is usually not granted in small treatment plants, a reliable

automated excess sludge withdrawal is required. Cyclic activated sludge

systems are well suited to keep a constant sludge volume at changing SVI

because the situation of the excess sludge discharge facility defines the

maximum level of the sludge blanket. On the other hand underloading can

also cause a loss of active biomass. Excessive sludge stabilisation reduces

the elimination capacity of the system. Hence the intensity of the treatment

process should be decreased at days with low influent flow. In case of an

intermittent feed or effluent flow the rise of the water level indicates

the loading and the optimum length of the aeration periods can easily be

controlled.

The results of this presentation are achieved

within the project "Comparison of technology, costs and environmental benefit

of wastewater treatment plants in mountainous areas in the Alps", which

is supported by the LIFE-program of the European Commission. This

project involves the construction of 15 small treatment plants under varying

and representative boundary conditions and the analyses of their operation

during a 4 years period. The influence of the inherent constraints of the

site (available energy source, possibilities of approach, supply and disposal,

hydrogeology, the characteristics of the wastewater, the altitude and temperature

etc.) on the choice of the proper treatment strategy is investigated. Moreover

the economic efficiency of the considered treatment system will be assessed.

Ingerle, K. (1998): Biocos-Belebungsanlage:

Kläranlagen Längenfeld und Pielenhofen.

gwf - Abwasser Special 139, Heft 14, S.32-35

Hagner, G. (1998): Inbetriebnahme einer Biocos-Anlage.

Diplomarbeit am Inst.f.Umwelttechnik, Universität Innsbruck