environmental benefit of wastewater treatment plants in mountainous areas in the alps

|

Comparison of technology, costs and environmental benefit of wastewater treatment plants in mountainous areas in the alps |

|

Energy demand and supply of different WWTPs |

Introduction

Trickling filter wastewater treatment plant refuge Gera (145 PE)

Trickling filter wastewater treatment plant refuge Adolf-Pichler (125 PE)

ESB wastewater treatment plant refuge Stuttgart (150 PE)

BIOCOS wastewater treatment plant refuge Nördlingen (145 PE)

Conclusions

The energy supply of operating the wastewater treatment system should not be affected by the energy consumption of managing the refuge and vice versa. We can distinguish different approaches how to integrate the energy demand of the treatment plant into the energy supply system of the refuge – or how to couple the energy supply of the treatment plant and the refuge respectively:

- Joint energy supply:

If there is a sufficient energy production on site and the energy demand of the waste-water treatment plant is relatively small in comparison to the total energy consump-tion of the refuge there is no reason to create separate energy supply systems (e.g. water power, continuously operated aggregates or CHPs = coupled heat-power-plants).

- Joint energy production and separate energy storage:

In case of energy shortage the energy demand of the treatment plant is in competition to other consumers. To prevent a poor supply of the wastewater treatment plant a separate battery set is suggested which is backed up by a joint energy source

(e. g. aggregate, photovoltaics).In the following different energetic situations of designated treatment plants are described:

- Separate energy supply:

In the case the energy supply system of the refuge cannot afford additional power consumption, an autarkic supply system can be considered (e.g.. photovoltaics). It should be noted that additional maintenance is required.

Trickling filter wastewater treatment plant refuge Gera (145 PE) |

The plant layout is adapted to the sufficient incline of the terrain so that the wastewater passes all parts of the mechanical-biological wastewater treatment plant in free flow. A gravity driven swell device distributes the effluent of the septic tanks alternating onto the both halves of the surface of the biological trickling filter. Even in periods without electrical energy supply the wastewater of the refuge is mechanically treated and at least partly biologically.

To increase the biological efficiency the effluent of the fixed film reactor is pumped back to mix with the influent by means of a submerged 230VAC/150W pump. It works intermittently controlled by a float switch. With an total operation time of about 8 hours a day the electric power consumption is about 1.2 kWh per day.

Trickling filter wastewater treatment plant refuge Adolf-Pichler (125 PE) |

When the wastewater treatment plant was built in 1994 energy supply for the refuge was generated for 100% by a diesel fuel generator. There was no other energy supply. Not even an emergency supply with battery backup. Two separate autarkic energy supply systems (e.g.. photovoltaics) were constructed: a small one for emergency lighting and main illumination without the fuel generator in work (refuge: 2*53 Wpeak + 150 Ah/24VDC battery) and a larger one for wastewater treatment (10*53 Wpeak + battery 490 Ah/24VDC). Nowadays a small hydro power plant helps to reduce operation hours of the fuel generator to a minimum. The power supply of the wastewater treatment plant is still fully autarkic working on photovoltaics.

In order to improve the biological efficiency the effluent flow of the fixed film reactor is pumped back internally to the influent by means of two alternately working submerged 24VDC/50W pumps. A gravity drive swell device distributes the mixed influent alternating onto the both halves of the surface of the biological trickling filter.

The surplus sludge from the bottom of the secondary settling tank is recycled into the primary settling tanks with a total pumping time of about 20 minutes a day by a submerged 24VDC/250W pump. Working at maximum load and normal recirculated flow the daily energy consumption is – with measured wattage values - about:

Recirculation pump(s) (24VDC/27W):

1 * 27 W * 24 h/d

= 0.65 kWh per day

Surplus sludge pump (24VDC/210W):

210 W * (8/60 h/d)

= 0.05 kWh per day

Programmable logic controller:

7.5 W * 24 h/d

= 0.20 kWh per day

True total electric power consumption working at full load:

= 0.90 kWh per day

ESB wastewater treatment plant refuge Stuttgart (150 PE) |

Operation of the plant - fine bubble aerators, air seal device, surplus- and clear-water syphons - is exclusively done by compressed air from two linear air pumps. The electro-magnetically-operated air valves are opened cyclically by a small programmable logic controller. All the components with energy consumption are assembled in one control unit which is mounted on the cellar wall of the refuge. Working at maximum load and main switch on MAX (MEAN, MIN) the daily energy consumption is about:

Linear air pumps (230VAC/225W):

2 * 225 W * 14.5 h/d

= 6.5 kWh per day

Electro-magnetically-operated air valves:

10 W * 14.5 h

= 0.1 kWh per day

Programmable logic controller:

10 W * 24 h/d

= 0.2 kWh per day

Total electric power consumption about:

= 6.9 kWh per day

BIOCOS wastewater treatment plant refuge Nördlingen (112 PE) |

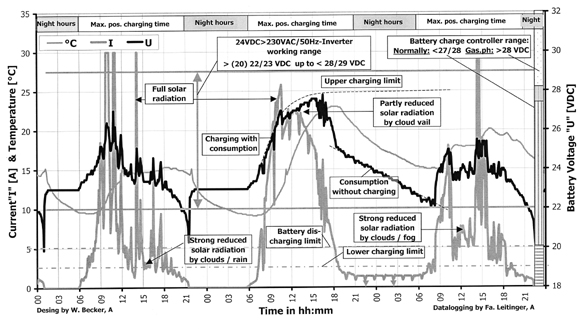

The photovoltaic plant with a total of 1100 Wpeak generates in 8 hours at full solar irradiation – without shadowing effects by clouds, cirrus etc. - a total maximum of 8.8 kWh. The effluent of the settling tanks is biologically treated by a Biocos treatment plant. There is only one instead of two linear air pumps used and electro-magnetically-operated air valves, fine bubble aerators, pumping of surplus-, activated sludge recirculation and clear-water and a programmable logic controller.

The difference to the above described ESB plant is that the linear air pump is working continuous as long as there is energy from the battery/inverter-combination. It provides the air cyclically to the fine bubble aerators in the aeration tank - or to one of the air operated surplus-, recirculation or clear-water syphons in the SU-tank. During pumping time there is no aeration of the activated sludge tank. Daytime and solar irradiation is corresponding with the steady consumption of energy and load of the wastewater treatment plant. The required energy consumption within 24 hours is calculated as followed:

Linear air pumps (230VAC/225W):

1 * 225 W * 24 h/d

= 5.4 kWh per day

Electro-magnetically-operated air valves:

10 W * 24 h

= 0.3 kWh per day

Programmable logic controller:

10 W * 24 h/d

= 0.2 kWh per day

Total electric power consumption about:

= 5.9 kWh per day

The weather dependant energy production is used to run the biological treatment according to increased load conditions. (See fig.1: 24 hours operation on the second day with full irradiation is indicated by over-night discharge beyond 22VDC battery voltage).

Activated sludge systems generally need more technical equipment and show higher energy consumption for the required oxygen input. Substitution of electric pumps by air-driven siphons (buoyancy pumps) increases the reliability of the activated sludge process and decreases the connected wattage so far that it is possible to operate an optimised activated sludge system by photovoltaics with appreciable investment and operation costs.