environmental benefit of wastewater treatment plants in mountainous areas in the alps

|

Comparison of technology, costs and environmental benefit of wastewater treatment plants in mountainous areas in the alps |

|

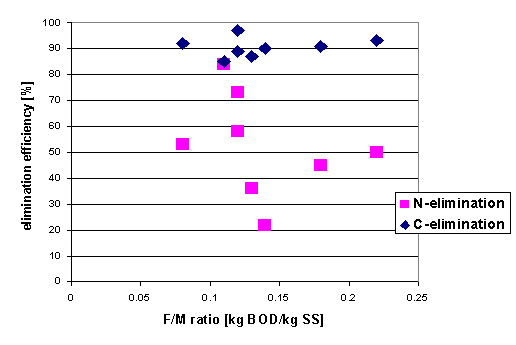

The main design parameter of activated sludge systems is the sludge loading represented by the daily organic load per aerated sludge mass (F/M ratio in kg BOD / kg suspended solids). Fig.1 shows the range of applied design F/M ratios between 0.08 and 0.22 kg BOD/kg SS. The design calculations have been based on different assumptions of sludge concentrations which varied between 3.0 and 5.0 g/l mixed liquor suspended solids. These values are in the range of optimum sludge concentrations in municipal wastewater treatment plants (compare the German standards ATV A131).

The achieved treatment efficiencies concerning COD elimination were in the range between 85 and 97 % (average of annual measurement values). Nitrification shows a much less stabile performance (note that nitrogen elimination is not required in remote areas by Austrian water legislation). The observed N-elimination efficiencies were between 22 and 84 %. Obviously the achieved nitrogen elimination does not depend on the designed sludge load. It is a remarkable fact that the measured sludge concentrations differed significantly from the designed ones. In general the measured sludge concentrations achieved only half the values expected from design (around 2 g/l). Hence the actual sludge F/M ratio reaches values around 0.4 g BOD/g SS during high-loaded periods and nitrifying organisms are washed out. But results also indicate that generously designed treatment plants do not necessarily achieve a higher total sludge mass because of poor sludge settling properties or excessive sludge stabilisation during low-loaded periods.

Concluding from these results a satisfying COD elimination has been achieved by all differently designed activated sludge plants. Nitrogen elimination efficiencies depend strongly on local wastewater characteristics and not so much on the designed F/M ratio or sludge age respectively.

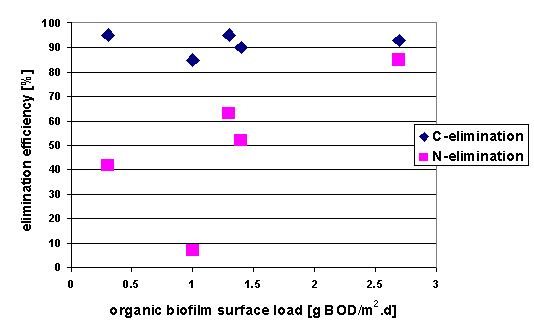

Therefore similar conclusions can be drawn as for activated sludge systems: There is a significant difference between the designed biomass and the actual active biomass in the system. The best results have been achieved by systems with at least two stages with different filter media and efficient splash distribution of wastewater on the provided surfaces for attached growth. Synthetic support material with high specific surfaces up to 200 m² / m³ has been proven suitable for the high-loaded first stage while especially for a second or third stage sand or soil filters showed better results. In general the performances of the monitored biofilm systems have been improved until the second year of operation. Obviously attached growth is more difficult on fresh and smooth surfaces.