environmental benefit of wastewater treatment plants in mountainous areas in the alps

|

Comparison of technology, costs and environmental benefit of wastewater treatment plants in mountainous areas in the alps |

|

Site description and boundary conditions

Design and treatment efficiency

maximum daily organic load [PE]

180 maximum hydraulic load [m3/d]

6.4

annual organic load [kg BOD/a]

330

altitude [m a.s.l.]

1970

sensitivity [hydrogeology, protected area ...]

well, limestone

lagal requirements [BOD elimination]

90 %

operation period [season]

summer

energy supply [type, kW]

Photovoltaic, 0.3; Aggregate, 17

means of transport [type]

supply cable car

existing WWTP [type, condition, volume l/PE]

grease trap, 2-chambers, poor condition

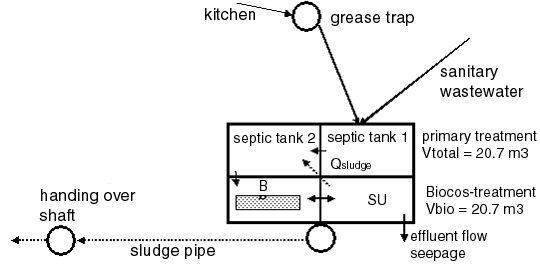

Fig. 4.8: Flow scheme of the WWTP Coburg Refuge

Fig. 4.10: Set of batteries in the background and charger and inverter in front.

Loading of the biological treatment

WWTP Coburg Refuge seasonal average max. week max. day loading [PE40] 40 80 180 BOD 5-load [kg/d] 1.6 3.2 7.2 influent flow Q [m3/d] 3.4 5.0 7.5

Design according to the F/M ratio in the max. weekVaerob = 3.0 x 1.5 x 2.3 m = 10.35 m3 (volumen B-tank)

Maerob = 10.35 m3 x 3.6 kg SS/m3 * 3.7 = 26 kg SS (aerobic sludge mass)

BTS = 3.2 kg BOD5/d : 26 kg SS = 0.12 kg/kg.d (aerobic sludge loading)

OB = 3.2 x 3 kg O2/kg BOD5 : 24 h = 0.4 kg O2 /h (oxygen demand)

Energy demand

max. power

[W]max. electric work

[kWh/d]mean electric work

[kWh/d]1200 18.7 18.7

Treatment efficiency

date

[dd.mm.yyyy]

CODeffluent [mg/l] NH4-Neffluent [mg/l] NO3-Neffluent [mg/l] CODelimination [%] Nelimination [%] loading

[% v. PWmax]29.07.1999 315 72 4 81 37 -- 08.09.2000 70 41 1 94 74 37 21.07.2001 55 7 16 92 62 43