environmental benefit of wastewater treatment plants in mountainous areas in the alps

| Comparison of

technology, costs and environmental benefit of wastewater treatment plants in mountainous areas in the alps |

|

General

Wastewater treatment plants

Wastewater treatment

Sludge management

This section gives a survey on the variety of different technical options for wastewater treatment in mountainous regions. The systematics of different treatment strategies will be presented with the 15 constructed treatment plants serving as case studies.

In order to get a more detailed description of a treatment plant either click directly on the name of the refuge or on the particular treatment system (represented by the coloured areas in the following figures).

Once again it should be outlined that this project has been funded by the EU-Life-Program at a rate of 50 % of the eligible costs and therefore all results of the project have to be available for interested persons. Details and additional information which cannot be presented within the limits of this homepage can be requested from the German Alpine Association (Deutscher Alpenverein e.V., Referat für Hütten und Wege, Von-Kahr-Strasse 24, D-80997 München).

Following 15 treatment plants have been constructed during the current Life-project:

Primary wastewater treatment

Primary wastewater treatment systems are applied for the separation of floating compounds (e.g. oil and grease) which have to be disposed separately and of solids which are a matter for sludge treatment. In most cases is the primary treatment the preliminary step to the biological treatment. Only 2 treatment plants ([02] and [05]) in the course of the Life-project are restricted exclusively to primary treatment. Following treatment strategies have been applied:

In almost all treatment plants within the Life-project the wastewater from the kitchen is led to a grease trap. Only in 2 cases ([02] and [12]) the sanitary installations in the house did not allow a separate collection of the kitchen wastewater. Septic tanks are the most common systems for solids separation and have been mainly designed as two- or three chamber tanks. Most of these systems at the sites have been ready for continued operation or required minor adaptations. Moreover a mechanical solids separator ([07]), a filter bag system ([05]) and two compost-toilets ([02] and [03]) have been installed within the Life-project.

Biological wastewater treatment

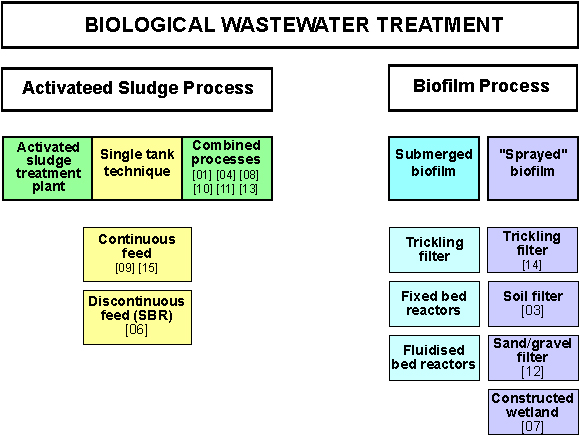

The following scheme represents the systematics of the most commonly applied aerobic biological wastewater treatment systems:

The applied treatment systems show a focus on cyclic activated sludge systems. Also a trickling filter, a compact soil filter and a planted soil filter have been installed. Finally a wastewater pond was applied.

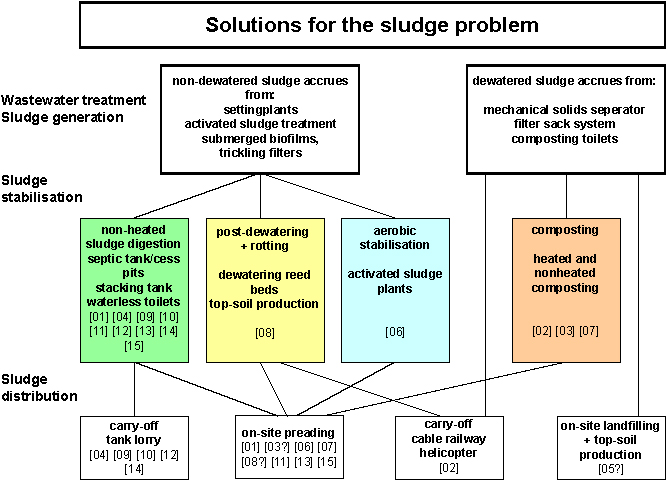

Sludge treatment and –disposal depends on the wastewater treatment system which determines the consistency of the produced sludge. Corresponding to the above described wastewater treatment either dewatered or undewatered sludge is considered. Different options of sludge management are listed in the following scheme:

Activated sludge systems have been installed in combination with septic tanks and the biological waste sludge has been stored together with the primary sludge. During the season in this septic tanks a slow unheated anaerobic digestion occurs with only minor stabilisation effects. Only at one site (Höllentalanger refuge) a sludge drying bed is operated. At another site (Essener/Rostocker refuge) the total raw wastewater flow is fed to the biological reactor and the sludge is aerobically stabilised. At two sites a heated composting process is applied (compost toilet at the Brandenburger refuge and mechanical solids separator at the Hermann von Barth refuge) and at one site an unheated composting process (Brunnstein refuge). In case that the refuges are accessible by a lorry the stored sludge is transported down to the valley. At the other refuges the sludge is disposed on-site (seasonal land application). The composted sludge from one site located in a glacier region is carried off by a helicopter.